Start your quotation journey here

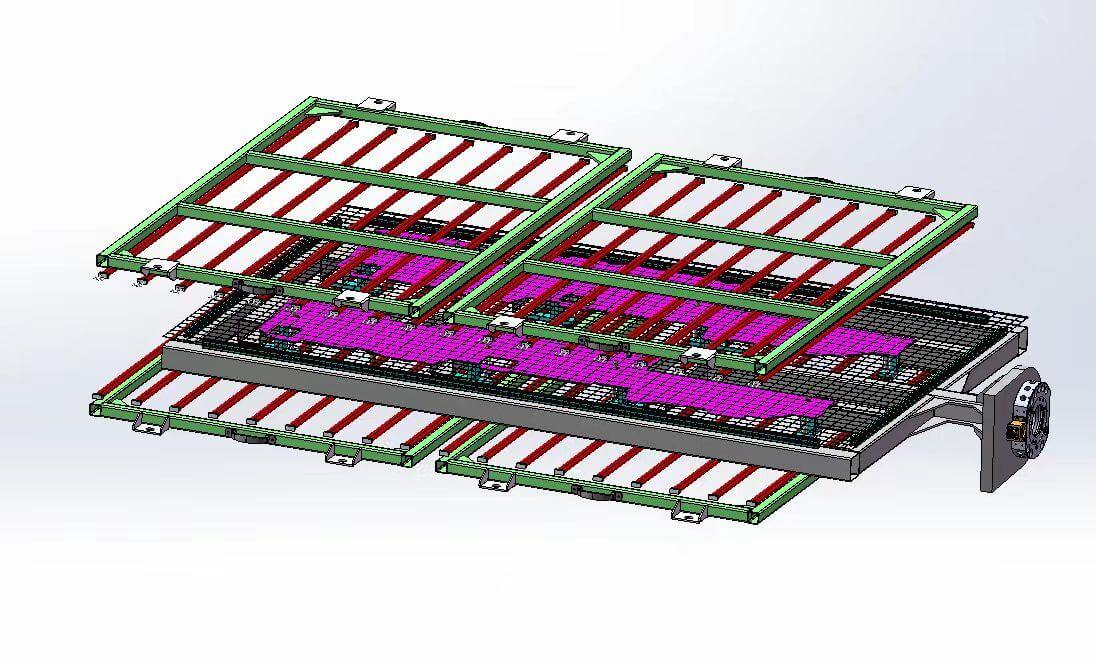

An infrared heating oven for car interior production is a specialized heating system used in the manufacturing process of car interiors. It is designed to efficiently and uniformly heat various components of the car interior, such as seats, dashboards, door panels, and other trim pieces.

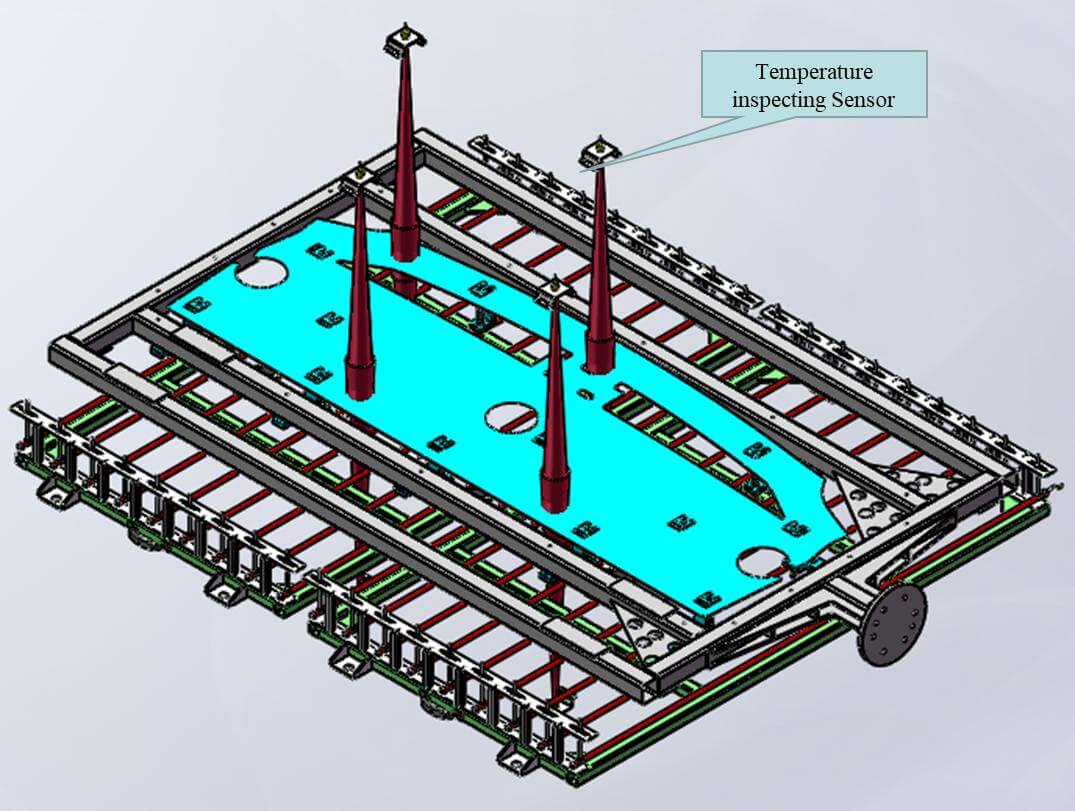

The infrared heating oven utilizes infrared radiation to transfer heat directly to the car interior components. This method allows for energy consumption saving and fast temperature raising and heating. The whole process should be finished less than 1min, which meets the requirement of mass production line.

During the production process, the car interior components are placed inside the infrared heating oven, and the heating elements emit infrared radiation that penetrates the surfaces of the materials. This radiation is absorbed by the materials, causing them to heat up quickly and uniformly.

Infrared heating ovens for car interior production offer several advantages. Firstly, they provide fast and efficient heating, reducing production cycle times and increasing productivity. Additionally, the precise control over the heating process ensures consistent quality and minimizes the risk of defects or imperfections in the car interior components.

Furthermore, infrared heating ovens are energy-efficient compared to traditional heating methods. They require less time to reach the desired temperature and can be easily adjusted or turned off when not in use, saving energy and reducing operating costs.